- Personal Care and Consumer Goods

- Release Control Additives Can Change Your Life

Release Control Additives Can Change Your Life

If you have ever removed a label, peeled a sticker, or tried to start a tape or double-sided tape, you have experienced how matching the silicone release coating to the adhesive works. If you have ever felt frustration because the label tore, the sticker fell off or the tape wouldn’t unroll, you have also experienced a mismatch in silicone release coating to adhesive. Too much of one but not of the other can cause unwinding issues in roll form, whether the material is “stuck” or whether it wants to continue to spiral and unwind after starting the roll. Using the properly matched silicone release coating that may have a release control additive (RCA) can help control how easily the material removes from the liner.

Background

Silicone release coatings provide a low release force against most adhesives and are cured to form a filmic-like surface to prevent/reduce silicone contamination migration into the adhesive surface. This type of coating helps any tacky substance, typically a pressure sensitive adhesive, from sticking together or onto another surface until ready to be removed for end use, whether that’s an adhesive from a tape or label. These coatings are deposited onto filmic or paper liners and wound into roll forms for further converting. The liner serves as a carrier to transport the roll without causing the roll to block, to protect the adhesive from contamination and attaching to objects prior to end use, and to hold the label or tape in place from the label or tape manufacturing step through printing and converting to final application. The liner serves as a carrier to transport the roll without causing the roll to block, to protect the adhesive from contamination and attaching to objects prior to end use, and to hold the label or tape in place from the label or tape manufacturing step through printing and converting to final application.

Applications and Science

As was mentioned above, any time you peel an adhesive from a backing (liner), in technical terms, you are using a peel speed and experiencing release force. The amount of force you need to separate the liner from the adhesive is based on the application. Some applications call for a low release force (usually high-speed, automated), some require a high release force (low speed, manual). Other applications require a high/low differential release when dual-linered adhesive films or double-sided tapes are needed. Since silicone release coatings provide the low release force, when you need a “tighter” or higher release force to separate the liner and adhesive, a release control additive may be needed.

To answer your question about release control additives, let’s look at the basic chemistry behind these polymers. RCA polymers are made of the same building blocks as silicone polymers, but instead of being a linear chain polymer, the resin, formed under very controlled conditions, creates a 3-dimensional structure, resembling linked “balls” or “cages”. These resins exist in different formats, such as vinyl groups embedded into the structure’s surface (most common). Other RCA resins exist with hydride functionality or have no functionality.

Figure 1. Computer Model of a theoretical structure of an MQ siloxane resin structure (Lin, Durfee, Knott 2009)

One common theory of how RCAs affect release is these resins form a network of domains (“cages”) across the surface of the release coating, and depending on delivery method, process, and resin type/formulation, either agglomerate into larger particles, or stay separated as discrete smaller particles widely dispersed across the surface. The different resin structures affect functionality and cage size which lead to different attraction sites at the interface.

The different resin structures affect functionality and cage size which lead to different attraction sites at the interface. Changes in release force are observed from the variations in the chemical structure, size, efficacy, and reactivity of the underlying silicone resin used in the RCA’s structure.

| RCA | Functionality | System |

| RCA-395 | Low Functionality, α-olefin diluent | Solventless Thermal |

| RCA-396 | Modifed, Low Functionality | Solventless Thermal |

| RCA-391 | Very Low Functionality, Non-Vi | Solventless Thermal |

| Mod-12045 | Medium Functionality | Solventless Thermal |

| PC-795 | Low Functionality | Emulsion |

| PC-197 | Low/Medium Functionality | Emulsion |

| PC-191 | Low Functionality Content, High efficiency | Emulsion |

Based on the formulation and resin selected, the efficiency of the resin can have a large impact. There is a minimum loading effect before larger release force impacts are observed. As the resin loading increases, the effect follows an exponential or polynomial increase curve.

Due to differences in the available adhesives, thicknesses, and characteristics, pre-determining the impact and attraction level between the adhesive, release coating, and RCA loading is difficult. Common trends or behaviors can be used to determine the initial selection of the RCA. All results should be tested and verified for any given application.

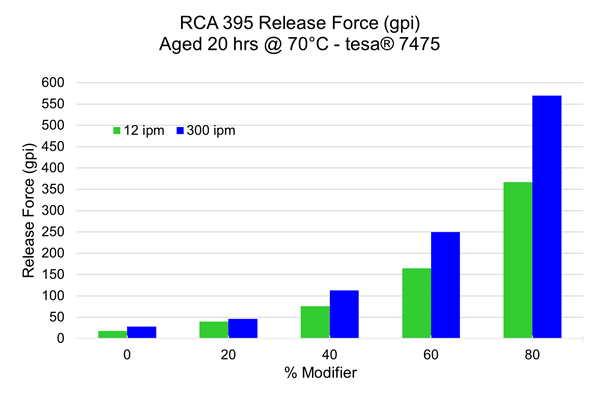

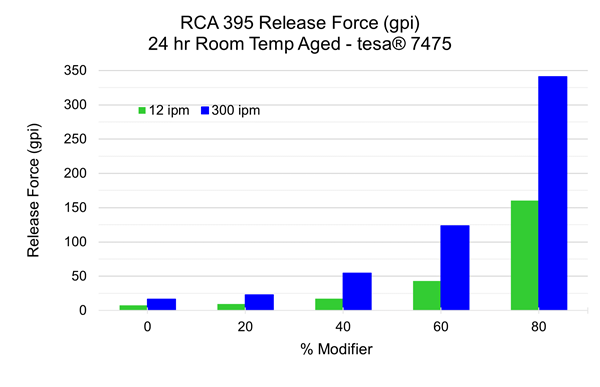

The following graphs compare the different release force values obtained at different peel speeds and aging conditions. In order to better understand the effects, SILCOLEASETM RCA 395 is shown below. The graphs show how the %RCA loading affects release values at listed conditions. Samples were coated on a pilot coater using a supercalendered Kraft (SCK) paper and cured by thermal ovens to reach a cure state identified as <5% extractable silicone, a common industry standard. Release force testing of the various samples was performed using tesa® 7475 acrylic tape.

SILCOLEASETM RCA 395 is highly efficient vinyl MQ RCA offering. When used appropriately, SILCOLEASETM RCA 395 offers many benefits when higher release values are required. When formulated properly with the appropriate base silicone polymer, catalyst, and crosslinker this RCA can be applied in high-speed coating processes. Likewise, it can be utilized in lower temperature curing applications.

Benefits:

- Tighter release with acrylic and rubber-based adhesives

- Comparatively lower concentration needed in formulation

- Low zippiness

- Low initiation spikes

- Anchorage to both filmic and paper substrates

- Double-sided coating is possible without blockin

As pictured, SILCOLEASETMRCA 395 can effectively meet a wide range of application needs. Whether you need a lower release level for an automated dispensing system or a higher release level for a manual peel application, varying the RCA loading along can achieve the results you need. To achieve a differential release, apply a low release base onto one side of the liner and a RCA modified, higher release, silicone onto the backside of the liner or carrier to achieve the release differential. Choosing the best system to meet your requirements should be determined with advice from a technical expert.