- Elkem

- Media

- News Articles

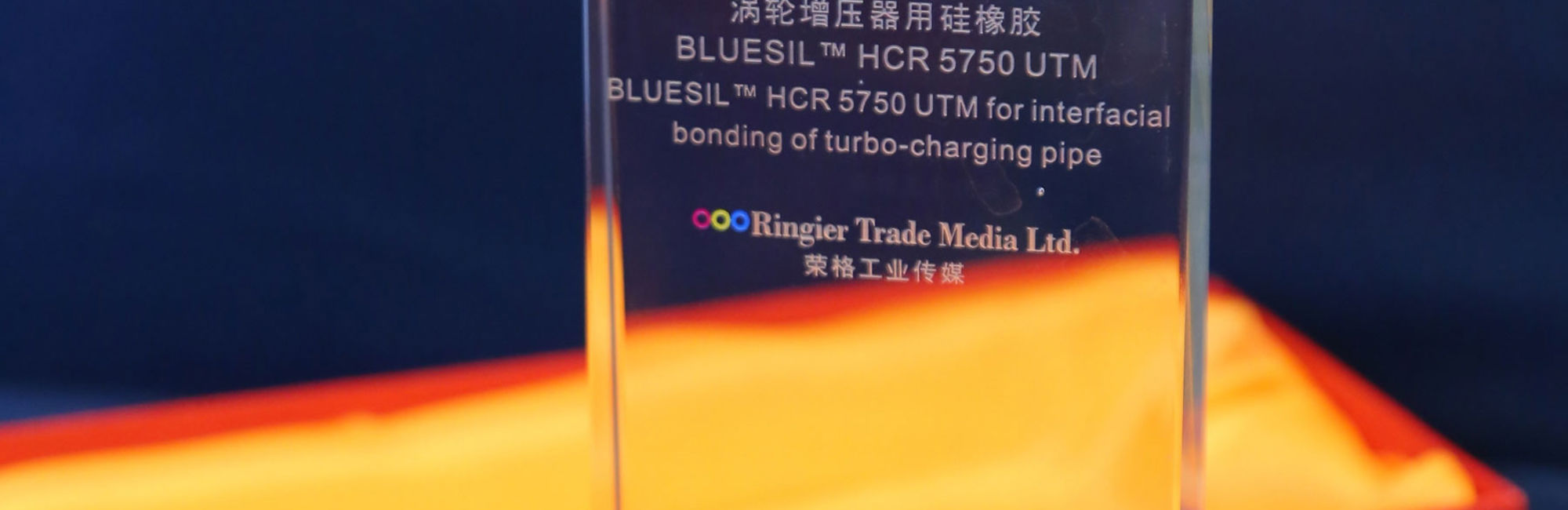

- Elkem Silicones won the Ringier Technology Innovation Award

Elkem Silicones BLUESIL™ HCR 5750 U for turbine application won the Ringier Technology Innovation Award

On March 9th, the 2021 Ringier Technology Innovation Award for plastic industry, which has been spotlighted, was grandly held at the Longemont Hotel in Shanghai. Elkem Silicones BLUESIL™ HCR 5750 U silicone rubber for turbine application won the “Rubber/Elastomer Material-Technology Innovation Award”.

BLUESIL™ HCR 5750 U is a heat resistant silicone rubber specifically designed for the interface bonding of turbine hoses in automobile "under the hood" applications. The BLUESIL™ HCR 5750 U after heated vulcanization and molding has good thermal stability, long-term heat resistance, and the maximum tolerable temperature can be as high as 230℃-250℃. Generally, the interfacial strength of traditional silicone rubber and fluoroelastomer after co-vulcanization and aging at 200℃ for 168 hours is about 0.1KN/m---0.5KN/m, while the interfacial strength for BLUESIL™ HCR 5750 U after co-vulcanization with fluoroelastomer is greatly improved thanks to the formulation and process design in full consideration of interfacial bonding and the impact of aging on the interfacial bonding. Especially, the interface peel strength of vulcanized rubber after aging at 200℃ for 168 hours is increased from 0.1-0.5KN/m of traditional silicone rubber to more than 2.0KN/m.

BLUESIL™ HCR 5750 U is satisfying with resistance to harsh environment of high and low temperatures, oil and liquid, and presents excellent flexibility at low temperatures. It perfectly solves the long-standing issue of the bonding between silicone rubber and fluoroelastomer in the turbine hose application, and effectively improves the vibration resistance, compression deformation resistance and service life under high and low temperatures of turbine hoses under harsh environments.

The main technical advantages include:

- Excellent bonding performance with fluoroelastomer FKM and silicone rubber VMQ, meeting the requirements of cohesive failure after aging at 200℃ for 7 days;

- Good high and low temperature thermal stability, long-term heat resistance, low temperature flexibility;

- Excellent balance of comprehensive capabilities including mechanical properties, strength, elongation, and tear resistance;

- It maintains good compression deformation even after experiencing extreme temperatures;

- Good calendering performance, making it convenient for customers to manufacture products.

As a trustworthy partner of the automotive industry, Elkem listens to the needs of the customers, gains insight into industry trends, actively responds to the challenges in development, and continues to provide customers with ideal product solutions and professional technical support. This award-winning product will be showcase at CHINAPLAS 2021 on 13th, to 16th, April, Welcome to visit our booth A141 Hall 17 at CHINAPLAS 2021.

About Elkem ASA

Founded in 1904, Elkem is one of the world's leading suppliers of silicon-based advanced materials with operations throughout the value chain from quartz to specialty silicones, as well as attractive market positions in specialty ferrosilicon alloys and carbon materials. Elkem is a publicly listed company on the Oslo Stock Exchange (ticker code: ELK) and is headquartered in Oslo. The company has more than 6,370 employees with 29 production sites and an extensive network of sales offices worldwide. In 2019 Elkem had revenues of NOK 22.7 billion.

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.