- Elkem

- Advanced manufacturing & industrial

- Refractories

Refractories

Versatile silicon-based products for the production of refractory materials

Addressing specific challenges in refractory applications

Shaped refractory products

Tailoring the performance of shaped refractories with microsilica

Shaped refractory products are used as prefired ‘building blocks’ that are installed using standard masonry techniques, and microsilica can be incorporated to meet the demands of individual applications.

Prefabricated refractory products

Microsilica for prefabricated refractory products

Prefabricated refractory products are directly installed in the functional parts of furnaces and kilns, and microsilica can be incorporated to meet specific processing and end-product features.

Castable refractory products

Tailoring the performance of castable refractory bricks with microsilica

Castable refractory products allow manufacturers to choose exactly the forms they need, and choosing formulations containing microsilica offers improved performance.

Materials for Refractories App

Find all you need to know about microsilica and other Elkem products for refractories in this app.

Our complete product range for refractories is composed of several material families

Silica fume / microsilica

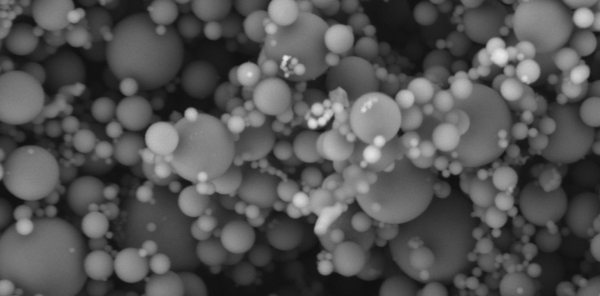

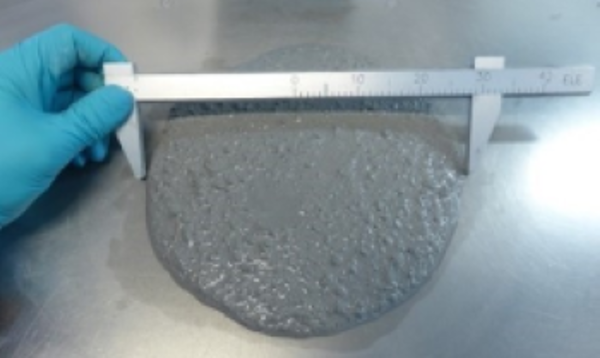

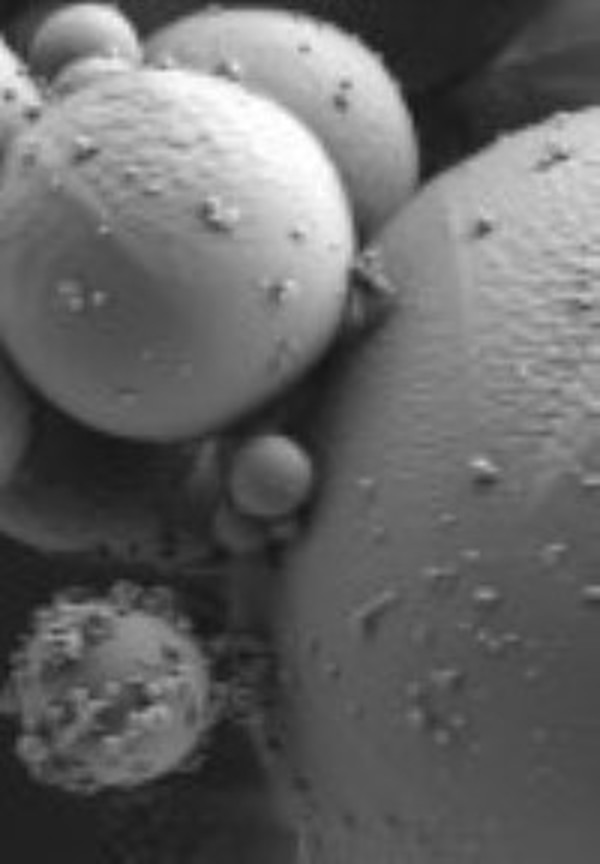

Silica fume, also known as condensed silica fume or microsilica, is a spherical sub-micron amorphous silicon dioxide used in many applications.

Silica fume is a co-product of silicon or ferrosilicon production, consisting of ultrafine (sub-micron), amorphous, non-porous, perfectly spherical silicon dioxide (SiO2) particles, with purity levels of 85 to 99 %. The main effect of these ultra-fine particles is to greatly improve particle packing and produce a highly pozzolanic reaction in concrete and other cementitious bond systems where the silicon dioxide reacts with calcium hydroxide, improving the strength development and durability of these materials.

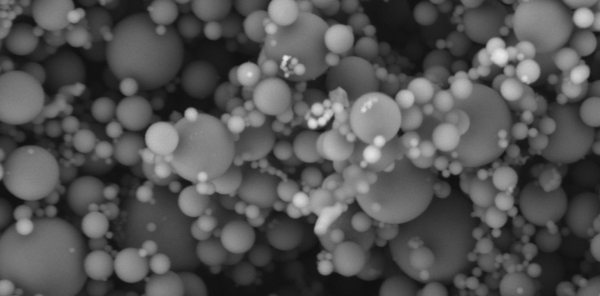

Silicon powder / micronized silicon

Silicon powder, also known as micronized silicon, is used for many different applications.

Metallurgical silicon is typically produced in a size of 0-100 mm, but for most applications further size reduction is required. The optimum particle size depends strongly on the final application. This means that, in many cases, some optimization work is required to find the most cost competitive solution.

Specialties for refractories

Our strategy is to develop specialty products and offer complementary products that will further advance the refractories technology and create value for our customers. These products include SIOXX™ Specialties, EMSIL-DRY™ and ALOXX™-Spheres.

Boron carbide

Boron carbide (B4C) plays a crucial role in the production of refractory items.

Boron carbide (B4C) serves as an anti-oxidant in the formulation process. Additionally, in the realm of high-performance ceramics and abrasives, boron carbide is utilized to enhance wear-resistance. At Elkem, we meticulously select our boron carbide to guarantee uniform quality, and our team of experts is readily available to offer guidance for your specific application.

Silicon carbide

Silicon carbide provides benefits for high-temperature, high-voltage and high-power applications

Silicon carbide is used for applications that require:

- Great mechanical strength, including high levels of hardness

- Great high-temperature resistance, combined to low thermal expansion and high thermal consistency

- Chemical inertness at all temperatures

- Variable electrical conductivity, including semi-conductor properties and non-linear electrical resistance

Fused silica

Our fused silica is mainly used in refractory, ceramic & glass manufacturing, investment casting and in other special applications.

Here are the characteristics of our fused silica:

- Uniform chemical composition with minimal impurities, resulting in exceptional high-temperature strength

- Outstanding dimensional stability, guaranteeing nearly exact castings

- Reduced thermal conductivity

- Complete absence of cristobalite

- Exceptionally low coefficient of thermal expansion

- Regulated particle size distribution

Sustainability at Elkem

To learn more about our sustainability initiatives, check our webpage.

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.