- Elkem

- Mobility & transportation

- Electrification & on-board electronics

- Thermal Management Materials for Battery Pack

Thermal management materials for battery packs

Silicones for thermal insulation, heat dissipation and fire protection in hybrid and electric vehicles

In the battery packs of hybrid and electric vehicles (H&EVs), thermal management materials help maintain an optimum temperature across the battery pack, as well as reduce fire risk. Silicones, with their high thermal stability and fire-retardant properties, are the favored materials for achieving these aims, and at Elkem we offer a range of high-purity silicones for thermal insulation, heat dissipation and fire protection.

Thermal management materials: Improving battery performance in H&EVs

As global production of H&EVs continues to increase, greater attention is being focused on optimizing the performance of the vehicle, and of the battery that powers it. One of the key factors that affects the performance of a battery is its temperature, with optimum battery power and longevity generally achieved between 15 °C and 35 °C.

Thermal management systems are used to keep temperatures across the whole battery assembly within this tight range during charging and discharging, reducing the risk of thermal runaway and preventing the outbreak of fire. Achieving these objectives is set to become an even greater challenge in the future, as H&EV technology becomes mainstream and demand increases for high-speed charging systems.

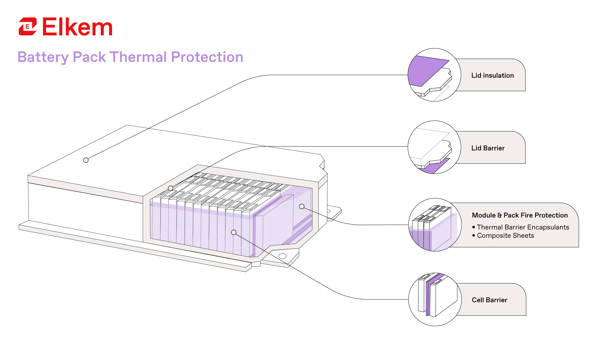

Thermal management systems typically involve a mix of materials that fulfill three roles:

• Thermal insulators to protect cells from high temperatures in other components. Foams are commonly used because of their low thermal conductivity and low density.

• Thermal conductors to efficiently remove excess heat from the base of the battery pack – for example, using circulating air or liquid. In this scenario, it is important that the boundary between the heat-generating components and the heat-dissipating components has minimal interfacial thermal resistance, requiring thermally-conductive gap-fillers or adhesives. These are often known as thermal interface materials (TIMs).

• Fire-retardant materials to prevent fire breaking out, and to contain its spread. Often this function can be accommodated by the thermal insulators/conductors.

Materials for managing heat

To achieve optimum performance for thermal insulation, thermal conduction and fire retardancy, it’s necessary to have a good understanding of the properties of the materials used.

These properties naturally include thermal conductivity, but other factors also need to be taken into account, with density and processability being of high importance, along with cost considerations.

Of the various material classes used for thermal management (such as epoxy resins and polyurethanes), silicones have become popular because of the following properties:

• High thermal stability – The ability of silicones to withstand temperatures over a wide range (from –80 °C to 250 °C) ensures reliable operating performance in extreme conditions.

• High fire-resistance – Unlike polyurethanes and epoxy resins, silicones are highly fire-retardant, and have very low emissions of smoke or toxic fumes.

• High flexibility – Silicones have a low elastic (Young’s) modulus, making them able to accommodate thermal expansion and absorb vibration, without cracking or placing stress on battery components.

• Variable viscosity – The viscosity of silicones varies from about 2500 to 400,000 mPa·s, making it possible to select the flow properties that fit in best with your production processes.

• Long lifespan – Thanks to their chemical inertness and high resistance to oxidation, silicones have a long lifetime in EV battery applications.

• Formulation adaptability – Silicones can be formulated to provide optimum properties for virtually every use scenario.

As well as thermal management, silicones can also be used for sealing of H&EV battery packs, and more generally to protect electronic components from damage.

Battery Thermal Management in Hybrid & Electric Vehicles

In this ebook, you'll discover the role of materials science in thermal management, find a comparative table of the different materials used...

Silicones for thermal management from Elkem

Silicones for thermal management from Elkem are available in foam, gel and adhesive form to cater for every requirement for thermal insulation and heat dissipation in H&EV battery packs.

In all cases, these products are also inherently fire-retardant, giving them a clear advantage over other materials used in the industry.

Silicone foams for thermal insulation

BLUESIL™ RT foams are two-part (RTV-2) silicone products with excellent insulating properties and intrinsically low weight, preventing battery packs from exposure to extremes of temperature while also addressing requirements for lightweighting.

Silicone gels and adhesives for heat dissipation

BLUESIL™ ESA silicones for heat dissipation are specially modified with fillers to enable them to conduct heat away from on-board electronics – for example, from the cells to the heat-sink, and between individual cells. The thermal conductivities of these silicones range from 0.4 W/m·K to 3 W/m·K, and they use a two-part (RTV-2) curing formulation, to enable quick, volatile-free curing of larger volumes.

These products typically take the form of silicone gels for filling gaps or encapsulating/potting components, such as gap fillers applications in the battery pack or OBC* applications. We also offer silicone adhesives that can bond two surfaces while also offering a degree of heat conductivity, without the need for primer. These grades are especially useful for bonding metal cooling plates to the battery.

Your partner for thermal management

If you’re thinking about whether to use silicones for thermal management in your H&EV battery packs, then here are some reasons why we’re a good choice:

• Experts in silicones – We’ve been producing silicones for over 70 years, and over that time we’ve developed world-leading expertise in silicone chemistry and applications. So we’re the people to talk to if you need advice about using our off-the-shelf products, or want to discuss developing tailor-made silicones for your applications.

• Worldwide support – Whatever part of the world you’re in, there will be an Elkem representative nearby who can provide expert help and advice, as well fulfil your training needs.

• Industry knowledge – Through our contacts with OEMs and Tier 1 suppliers, we keep on top of the latest trends in this fast-moving industry, and are ready to help with design, prototyping, assembly, maintenance and end-of-life.

• Sustainability – Environmental awareness runs deep at Elkem, and we’re ready to listen to your requirements for supply-chain sustainability.

*OBC = On-Board Charger

Optimizing safety and reliability of EV Battery Packs with Thermal Management and Sealing

Learn how silicone materials can help you improve the performance of your battery pack and protect it against harsh environmental conditions.

Related products

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.