- Elkem

- Mobility & transportation

- Electrification & on-board electronics

- Battery sealing solutions for battery packs

Battery sealing solutions for battery pack

Silicones for ensuring battery integrity in hybrid and electric vehicles

Battery sealing in hybrid and electric vehicles (H&EVs) is essential to maintain battery integrity and so eliminate safety issues and maximize product lifetime. Silicones are a high-performance option for producing both form-in-place and cure-in-place gaskets for H&EV battery packs, and at Elkem we’ve got the product range and application expertise that will help you make the perfect choice.

Battery sealing: Protecting electronics in H&EVs from moisture and dust

Battery performance and cost is widely recognized as a limiting factor in the uptake of H&EVs. This means that automotive manufacturers need to protect battery packs from the external environment, in order to extend cycle life and reduce the risk of battery failure.

Such protection is achieved by using carefully chosen materials to ensure a tight seal between the parts of the battery casing. Historically, pre-cut gaskets were used, but today it is more common to use an automatically-dispensed liquid product that is cured to form a good seal.

A formed-in-place gasket (FIPG) is produced by dispensing the sealant onto one surface and immediately placing the other surface in contact with it. This approach is used when a permanent seal is needed with good adhesion between the two surfaces, and/or when same-day assembly is desired.

A cured-in-place gasket (CIPG) is produced by dispensing the sealant onto one surface, and curing it, when necessary, with heat or light before placing the other surface in contact with it. This approach is used when the two surfaces need to be easily separated for inspection or maintenance.

Whichever method is used, the aim is to eliminate water ingress (and so avoid the risk of short-circuiting), as well as to avoid dust entering the battery casing and posing a fire hazard. The sealing performance achieved is defined using one of two ratings developed by the International Electrotechnical Commission, known as IP67 and IP68, and the best materials comply with the more rigorous IP68 rating. The use of gaskets also has a role to play in dampening vibrations.

The best materials for battery pack sealing

There are three main classes of material used for gasketing of H&EV battery packs – silicones, epoxy resins, and polyurethanes. Of these, silicones have several important advantages:

- High thermal stability – Silicones maintain their properties over a wider temperature range (–80 °C to 250 °C). This ensures superior sealing results and excellent stability under extreme conditions.

- High flexibility – Silicones have a low elastic (Young’s) modulus, making them far less rigid than epoxy resins and polyurethanes. This means that, although they maintain their shape, they are more tolerant of vibration and thermal expansion/contraction.

- Long lifespan – Silicones have a long lifetime in H&EV battery sealing applications, because of their chemical inertness and high resistance to oxidation and UV radiation.

- High fire-resistance – Silicones are inherently fire-retardant, and when they do burn, emissions of smoke or toxic fumes are very low – in contrast to polyurethanes and epoxy resins.

As well as battery pack sealing, silicones can also be used for thermal management in H&EV battery packs, and more generally to protect electronic components from damage.

Battery Thermal Management in Hybrid & Electric Vehicles

In this ebook, you'll discover the role of materials science in thermal management, find a comparative table of the different materials used...

Battery sealing solutions from Elkem

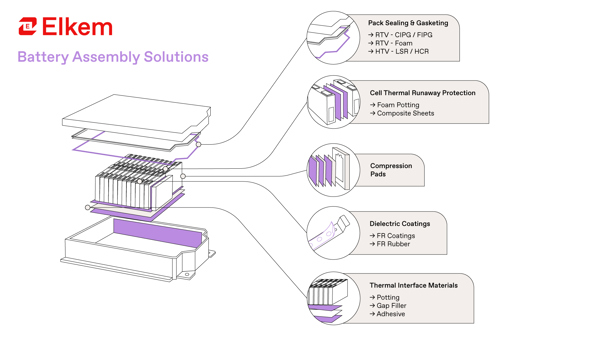

At Elkem, we supply four main classes of silicone products for sealing and gasketing battery packs in H&EVs:

- CAF™ 24 MF is a one-part (RTV-1) formulation that is suitable for both FIPG and CIPG processing. It is able to adhere to a wide variety of substrates, with particular strength for metal surfaces. With its high thermal resistance, it is especially useful in hybrid vehicles, where temperatures under the hood can be as high as in conventional vehicles.

- BLUESIL™ ESA 8352 A/B is a two-part (RTV-2) silicone product that offers a quick cure and good adhesion to a variety of substrates for FIPG and CIPG processes. Its excellent mechanical and adhesion performance makes it a good choice when resistance to vibration and shock is a priority, while it.

- BLUESIL™ RT foam is a series of ‘foamed-in-place’ two-part (RTV-2) silicone products that inherently provide lower density and improved heat insulation than conventional sealants. They are suitable for sealing various surfaces used in battery packs, and provide excellent resistance to compression deformation, giving them a long service lifetime.

- Other BLUESIL products are heat-cured (HCR) silicone rubbers that contain additives endowing them with exceptional heat resistance (–50 °C to 300 °C), mechanical strength and flexibility. As well as being suitable for battery gasketing, they are ideal for cables, hoses and anti-vibration pads.

Both BLUESIL™ ranges also have very low levels of volatile D3–D10 cyclic siloxanes, helping to improve plant air quality.

With this choice of silicone sealants from Elkem, you’re sure to find a product that will comply with the demands of your application, and that meets the requirements of IP67/IP68.

Expert support for battery pack sealing

Why should you talk to us about battery sealing for H&EVs? Here are a few reasons:

- Expertise in silicones – We’ve been producing silicones since 1944, and no-one is more familiar with the chemistry and applications of these materials. So we’re well-placed to help you, whether you need advice about the applications of our off-the-shelf products, or need to discuss options for custom silicone manufacture.

- Global reach – Wherever you’re based, we’ve got someone in your region who can provide expert support, training and collaboration.

- Industry contacts – We’re actively involved with OEMs and Tier 1 suppliers from the design stage, through to prototyping, assembly and maintenance services (and including disassembly and recycling).

- Sustainability – Supply-chain sustainability is a growing issue for automotive manufacturers, and we’re ready to listen.

Optimizing safety and reliability of EV Battery Packs with Thermal Management and Sealing

Learn how silicone materials can help you improve the performance of your battery pack and protect it against harsh environmental conditions.

Related markets

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.