- Elkem

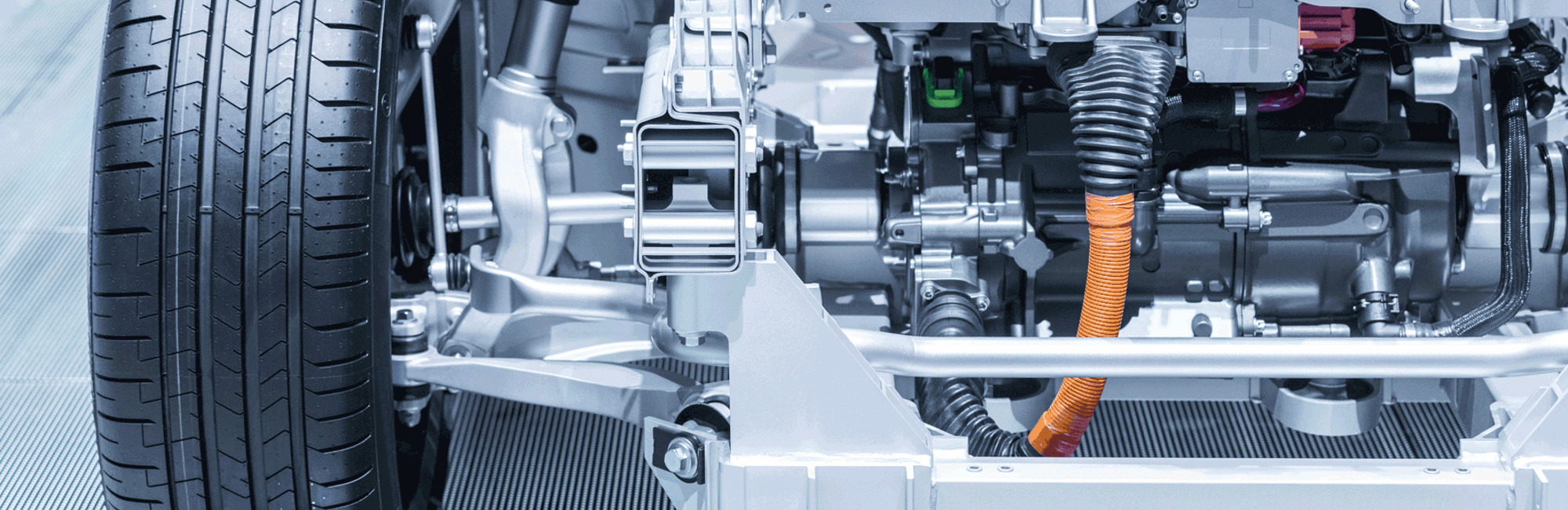

- Mobility & transportation

- Tires & safety systems

- Compacted graphite iron

Compacted graphite iron

Controlling vermicular graphite formation with foundry alloys

Compacted graphite iron is increasingly used in specialist automotive and transport applications, thanks to its combination of high tensile strength, good fatigue properties, and ease of machining. With our combination of expertise, product quality and global reach, you’ll find Elkem is your ideal partner for optimizing production of compacted graphite iron.

Compacted graphite iron: Fine-tuning product quality and improving production efficiency

Compacted graphite iron (CGI), also known as also known as vermicular graphite iron, contains carbon in the form of graphite ‘worms’ or compacts that are shorter and thicker than flake graphite in gray iron, and have more rounded ends. The form of the graphite compacts results in CGI having a high tensile strength and stiffness, while also retaining good fatigue properties and being relatively easy to machine.

At Elkem, we offer an unrivalled range of precision-formulated recarburizers, preconditioners, magnesium–rare earth treatment alloys, inoculants and inserts to ensure defect-free CGI castings, at the same time as streamlining production.

Recarburizers for compacted graphite iron

High-purity recarburizers are particularly useful for adjusting carbon levels in CGI base metal during charging of the furnace, and as a ‘trimming’ addition just before tapping from the furnace. Use of highly crystalline recarburizers ensures easy dissolution and maximizes carbon recovery.

Preconditioners for compacted graphite iron

The addition of preconditioners to CGI melts can help to enhance and stabilize the nucleation potential of the base iron, avoiding later nucleation ‘fade’ and resulting in better-quality castings.

Conditioners for compacted graphite iron

The introduction of magnesium–rare earth treatment alloys to molten iron in the treatment ladle generates an intense reaction, causing challenges of metal spillage, magnesium oxide fume, slag formation, loss of nucleation and variable magnesium recovery. These challenges can be largely overcome by using a specially formulated conditioner (also known as a cover alloy) in sandwich and tundish ladles.

Magnesium–rare earth treatment alloys for compacted graphite iron

With recarburization and preconditioning complete, the next step in the production of CGI is treatment of the melt with a magnesium ferrosilicon treatment alloy.

The use of carefully optimized grades of these alloys makes it easier to minimize the quantity used, avoiding the excessive fume, high slag generation and reduced nucleation that can result if too much is added.

Inoculants and inserts for compacted graphite iron

The addition of inoculants is an essential step in the treatment of CGI to ensure the carefully controlled precipitation of worm-like graphite compacts in a carbide-free matrix.

Inoculants can be added just before casting, or in the mold itself (when they are known as inserts).

The Elkem advantage

For many decades, Elkem has been assisting iron foundries around the world with their alloy requirements. We’re always willing to tailor our offering to the application in question, and we take pride in our attention to detail – only the best is good enough for our customers.

MORE ABOUT FOUNDRY ALLOYS

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.