- Elkem

- Healthcare

- Diagnostics & monitoring

- In vitro diagnostics

Medical-grade silicones for in-vitro diagnostic devices

Silicones are widely used in the production of components for point-of-care tests, and we supply a range of silicone products for various manufacturing requirements.

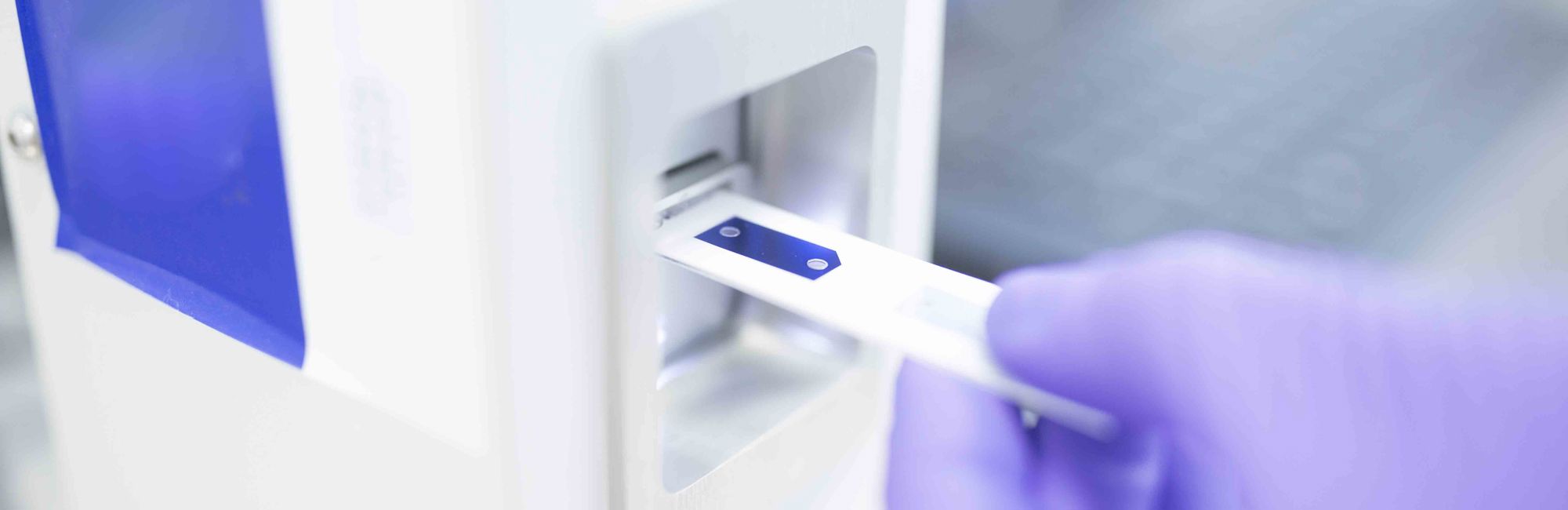

Manufacturers of diagnostic devices use medical grade silicones in the production of a wide range of products including point-of-care testing (POCT) devices.

In vitro diagnostics (IVD) POCTs are an emerging trend in the field of diagnosis as they include disposable and home health options for the patient. POCT devices are convenient since they are easy to use, eliminate the need of traveling to medical facilities and provide the test result within minutes. Among others, microfluidic cartridges are the heart of POCT devices.

Condensed on a few centimeters, these chips enable sample drawing, sample preparation and parallel analysis of various parameters. Silicones facilitate the fabrication on a micrometer scale and integration of valves, micropumps and other components. Utilizing Silbione™ silicone materials will provide various benefits to manufacturers of In vitro diagnostic point of testing devices including biocompatibilty and application-specific solutions to limit absorption of both proteins and drugs.

At the beginning of every treatment, there is a diagnosis. Whether by imaging in the local doctor’s office, invasive tissue sampling at the hospital or by point-of-care-testing right at the site of the patient: the diagnosis gives certainty to the Healthcare professional and provides feedback for the most suitable treatment against a specific disease. In this context it is important that the diagnostic device functions reliably. This requirement is not only valid for the diagnostic assay but includes every single component, like valves, tubes and the housing of the device as well.

Manufacturer of diagnostic or sensory devices use silicone elastomers among others in the production of disposable and home-health devices, microfluidic chips, gaskets and cushioning pads. For many applications the material of choice are silicone elastomers, not only because of their unique properties and ease of processing, but in particular due to its inertness.

Innovative medical device trends enabled by silicone

Unleashing Medtech innovation, getting through regulatory & supply hurdles

In this context, Elkem’s Silbione™ brand offers a powerful toolbox for the development and large-scale production of diagnostic devices and wearable solutions. Our product portfolio is ranging across the entire silicone technology tree and offers solutions for each stage of the development:

- Low-viscosity elastomers (RTVs) which are well-suited for the rapid and simple fabrication of prototypes.

- Durable liquid silicone rubbers (LSRs), which allow for high-volume production.

- High-consistency rubbers (HCRs), which are used in the extrusion of complex tubular geometries

- Silicone adhesives and sealants, which are used to assemble the device and protect it from moisture.

Experience the Silbione™ difference

Find out more about medical-grade silicones for healthcare & biomedical applications.

At Elkem Silicones, we have dedicated people located around the globe, committed to your success. Whether you are looking for a product recommendation, for customized silicone solutions, or for regulatory support, we have the people in place when and where you want them.

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.