Specialties for oilfield

Enabling drilling, cementing and well-stimulation processes to be carried out efficiently and safely

Improving production by reducing drilling/tripping times

Drilling for oil and gas is a very expensive process, often with a rig spread rate of $1 million per day. Operators therefore need to cut drilling times to a minimum.

This means using the highest quality specialty products that ensure rapid, safe and reliable drilling and completion operations and cement placement across the wellbore.

The Elkem specialty product portfolio offers custom-designed and cost-effective drilling and completion fluids and cement slurry systems that provide support for all essential functions. They not only provide excellent technical features, but are specially formulated to generate value solutions and business outcomes, based on capturing real value and streamlining operations.

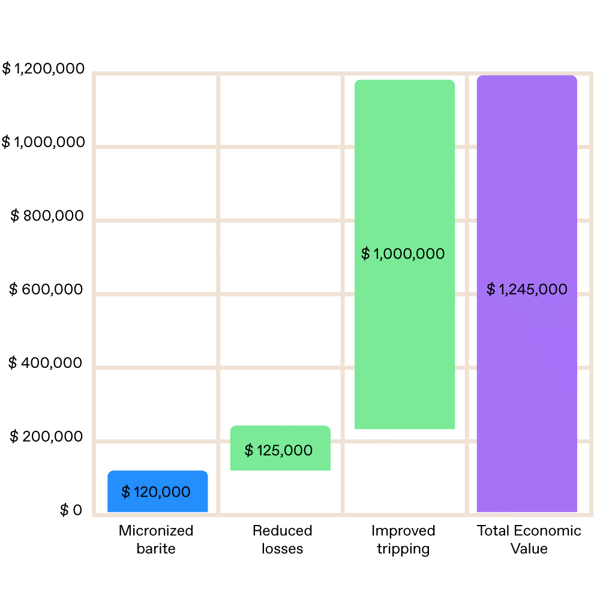

Below is a real-world example of how one Elkem specialty product, MICRODENSE®, saved one day’s tripping time compared to micronized barite, reducing operational costs by $1 million.

A full portfolio of added-value products

Elkem's products are used by service companies and oil & gas operators at every stage of operations. Here is a partial overview of some of our main products and how they contribute to enhancing different facets of drilling, cementing and well-stimulation processes:

MICROMAX® and MICROMAX® FF

MICROMAX® is a high-performance non-milled weighting agent used in drilling and completion fluids, cement slurries and spacers. By maintaining consistency through its particle size distribution (PSD) and almost perfect sphericity, its size and shape contribute to its unique properties. For example, it has an advantage over other weighting agents such as barite, which are milled and have angular morphology and a wide PSD.

The advantages of MICROMAX® include:

- Its micron-sized perfectly spherical particles that provide minimal sag, useful for producing ultra-low rheology fluids and slurries

- Its higher density (+15%) and hardness (+60%) compared to barite and its sphericity and particle size, which reduce abrasiveness significantly

- Its usefulness in a wide range of applications, including aqueous and non-aqueous drilling and completion fluids, cement slurries and cement spacers

- It is environmentally safe by nature, and PLONOR classified.

MICROMAX® FF is a free flow version of MICROMAX®, designed for easy mixing and usage. Once mixed into the cement slurry or spacer, it performs as effectively as MICROMAX®, offering excellent dispersion, particularly for high density applications and cement systems with flexible components or fibers.

MICROMAX®and MICROMAX® FF can both be used in a great variety of applications:

- Deepwater drilling

- HPHT and Ultra HPHT

- Coil-tubing operations

- TTRD, ERD, or other difficult well conditions

- Contingency or on-the-fly material in case higher density is needed.

MICRODENSE®

MICRODENSE® is a specially selected, high density, micronized ilmenite (iron titanium oxide, FeTiO), used for drilling and completion operations.

Its unique features include:

- Lower abrasiveness than common weighting agents and a magnetite content of less than 0.3% by weight

- Improved recovery of fluids at shakers, with less dilution required to maintain high hardness properties

- Partial acid solubility, making it suitable for drilling and completion of reservoir sections

- Reuse of the fluid for drilling and completion, lowering costs and operational time

- High hardness, preventing degradation, lower dilution rates and less surface losses.

MICROBLOCK®

MICROBLOCK® is a slurrified multifunctional microsilica product with high surface area and quality-controlled PSD. It reacts with calcium hydroxide to form more calcium silicate hydrate (C-S-H) crystal structures that bind cement, increasing compressive strength and lowering slurry permeability and controlling gas-migration.

Originally developed to control gas migration, MICROBLOCK® offers key slurry features including:

- Zero free water, low fluid loss, low viscosity, early strength development, high compressive strength, lower set cement permeability, improved bonding, stable cement slurry and corrosion resistance

- Improved bonding with the casing and formations, through extremely fine particles working as a 'packing' agent (physical and chemical) between larger particles such as cement, weighting agents or silica flour, compensating for volume shrinkage in setting cement; efficient in casings at all slurry densities or downhole temperatures

- Pozzolanic reaction, ensuring better set-cement properties and zonal isolation. The fine particles of MICROBLOCK® also enhance the control of fluid loss, packing cement slurry pore spaces, reducing permeability of the cement filter cake

- Corrosion resistance through occupation of spaces between larger cement grains, resulting in a dense matrix with set cement benefitting from lower permeability and better corrosion resistance than standard cement.

MICROLITE® P

MICROLITE™ P is a dry, amorphous, spherical microsilica. It is pozzolanic and creates extra binder phases, resulting in lower set-cement permeability. It acts as an extender, lowering cement slurry density and enhancing compressive strength, with zero free water, low fluid loss, low viscosity, early strength development, high compressive strength, improved bonding, stable cement slurry and corrosion resistance to the cementing fluids.

Elkem offers a full range of cementing additives covering all your needs. This includes products for use from low to high temperatures, including AMPS synthetic fluid loss additive for cement, dispersants and retarders.

We also offer products from the lowest to the highest densities, with the range covering inert lightweight particles like Cenospheres or glass bubbles all the way to proprietary Micromax® FF non-settling, low-rheology cement slurry weighting agent. Elkem also offers a full list of dispersants, retarders and defoamers for use across the whole temperature spectrum.

ML-31

ML-31 is a liquid latex additive used to lower equivalent circulating density (ECD) and control gas-migration in cement slurries. It can be used in many applications and at various temperatures up to 400°F (204°C) bottom hole circulating temperature (BHCT). It can be used in slurries for salty environments and, with the addition of LS-80, can be used in salt saturated slurries.

Microfibers

Microfibers are high performance monofilament fibers used to control losses and prevent cracks in the set cement matrix. They are compatible with most cementing systems and additives, to enhance the mechanical properties of set cement without affecting cement slurry performance properties.

Related pages

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.