What are polymer additives?

Polymer additive products for rubber compounds, thermoplastics and coatings.

Polymer additives: sustainably improving processing, product performance and safety

The SIDISTAR™ and SIDISHIELD™ product families are specially developed sustainable additives for rubber, thermoplastic and coating formulations. These multifunctional additives provide improved performance in viscosity control, processing, dispersion, flame retardancy and dynamic fatigue.

Our products are available worldwide and are REACH compliant.

Understanding the basic chemistry of SIDISTAR™ and SIDISHIELD™ products

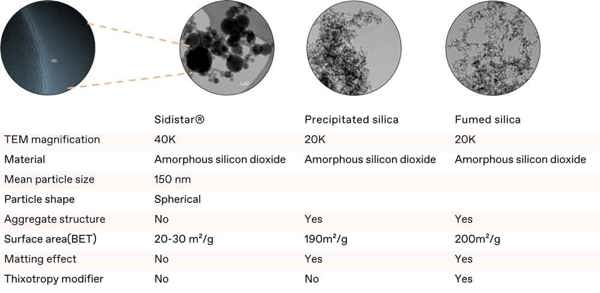

Basically, all the characteristics and functionalities of these products are based on physical effects and come down to their specific morphology. These silica-based products consist of perfect spherical particles of 150nm in size which are dispersible in primary particles. Elkem’s products are very different from silicas already in use in the polymer industry, as shown in the table:

To summarize, Elkem additives SIDISTAR™ and SIDISHIELD™ all feature small (submicron) amorphous (non-crystalline) silicon dioxide particles and water content.

The spherical shape and perfect dispersibility of the particles provide the following advantages:

- Ball bearing effect, resulting in better processing (extrusion, spraying, mixing) and surface appearance

- Pearl mill effect, bringing better dispersion and homogeneity

- Spacer effects, preventing re-agglomeration

- Optimized particle packing, allowing improved flame retardancy due to char integrity, lowering penetration of liquids in coating systems

Elkem SIDISTAR™ products: high-performance materials for rubber compounds and elastomers

Here is a non-exhaustive list of our product offering for rubber compounds and elastomers

SIDISTAR™ R300

SIDISTAR™ R300 is a specially designed grey-coloured process modifier consisting of spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

SIDISTAR™ R320

SIDISTAR™ R320 is a specially designed light-coloured process modifier consisting of spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

SIDISTAR™ R320U

SIDISTAR™ R320U is a specially designed light-coloured process modifier consisting of spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

SIDISTAR™ M220ST01

SIDISTAR™ M220ST01 is a specially designed light-coloured process modifier consisting of spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

SIDISTAR™ XP320ST69

SIDISTAR™ XP320ST69 is a specially designed light-coloured process modifier consisting of surface modified spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

The SIDISTAR™ R-product series is specially designed for use in rubber compounds. This line is used in a wide range of applications for finished products and serve many sectors, including the construction industry, domestic appliance manufacturing and the automotive and public transport industries.

Applications include (but are not limited to)

- Flame retardant compounds for roofing membranes, cables and conveyer belts

- Fatigue-resistant anti-vibration parts such as engine mounts, antivibration pads, power transmission belts and bushings

- Tires, hoses, sealing systems, profiles, etc.

Elkem SIDISTAR™ products: a wide choice of additives for thermoplastics

Elkem SIDISTAR™ products

SIDISTAR™ T120

SIDISTAR™ T120 is a specially designed light-coloured process modifier consisting of spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

SIDISTAR™ T120U

SIDISTAR™ T120U is a specially designed light-coloured process modifier consisting of spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

SIDISTAR™ M220ST01

SIDISTAR™ M220ST01 is a specially designed light-coloured process modifier consisting of spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

SIDISTAR™ MB F21

SIDISTAR™ Master-Batch series are designed to provide you with easy dispersibility of Sidistar® in thermoplastics.

Product data sheet

The SIDISTAR™ T-product series is designed for use in thermoplastics, thermo-hardeners and composites. Due to the composition of the material, it is compatible and suitable for most thermoplastic resins. These grades are used in a wide range of final product applications, serving sectors such as the construction industry, domestic appliance manufacturers and the automotive and public transport industries.

Applications include (but are not limited to)

- Flame retardant compounds for roofing membranes, cables and electronics and white goods

- Nucleating agents for foam building

- Processing aids for organic-filled composites such as wood, plastic and rice husk fiber composites and extrusion spinning applications.

- Elkem experts, technicians and sales staff are available to explore the right solutions for your thermoplastic applications.

Elkem SIDISHIELD™ products: a versatile offer of additives for coatings

- The Elkem SIDISHIELD™ product series: high-performance additives for coatings.

- The Elkem SIDISHIELD™ C-product series is designed for use in liquid systems such as paints, coatings, inks and adhesives.

These are two of our main products for coatings:

SIDISHIELD™ C25

SIDISHIELD™ C25 is a specially designed light-coloured coating additive consisting of spherical, submicron particles of amorphous silicon dioxide.

Product data sheet

SIDISHIELD™ C30ST01 XP

SIDISHIELD™ C30 ST01 XP is a surface modified, light-coloured, coating additive. It is an inert (non-reactive) additive with submicron spherical particles of amorphous (non-crystalline) silicon dioxide.

Product data sheet

SIDISHIELD™ coating additives provide specific processing and product quality advantages in several coating applications, including improved dispersion, easy mixing, smoother flow, better coating homogeneity, finer pigment particles, reduced pigment loading to prevent re-agglomeration of pigments (spacer effect), improved suspension stability because of their milling effect (shortening processing time), better particle packing (enabling the upgrade of the wet scrub class), longer paint shelf-life, reduced need for addition of solvents (lower VOC content), hardness, etc.

These advantages, as is the case for all SIDISHIELD™ and SIDISTAR™ products, are based on the perfectly spherical, submicron particles of amorphous silicon dioxide in the products.

Applications include usage in all types of coating systems: solvent free, waterborne, and solvent based, including UV and powder coatings, designed to improve hydrophobicity, as well as dispersing agents and spacers in pigment concentrates.

Collaborative R&D for product development and sustainability

Beyond its high-quality polymer additive product offering, Elkem is engaged in collaborative R&D with several dozen companies. In many cases, Elkem works on exclusive and confidential upstream innovation projects, designing and testing formulations that in some cases are patented by Elkem customers.

Sustainability at Elkem

To learn more about our sustainability initiatives, check our webpage.

Polymer additives applications

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.