- Elkem

- Advanced manufacturing & industrial

- Molding & printing

Molding & Printing

Unlocking possibilities with versatile molding and 3D printing solutions

We unleash creative possibilities with versatile molding & printing solutions

Silicone molds for general molding

Customized solutions for a wide range of applications, ensuring perfect reproduction of every detail

Molding is used for the reproduction of fine details in artwork and architecture, through to the making of large prototypes for such industries as transport, renewable energy and foundry work, and in areas such as food, fashion and cosmetics.

Mold-makers and die-casters require very specific materials with the right mechanical properties that facilitate their processes and guarantee quality products reliably, efficiently and cost-effectively. Increasingly, they must meet very demanding regulatory standards, at all stages from manufacturing to end-user safety, and they must develop more sustainable, environmentally friendly and non-toxic products, while reducing waste during the mold-making process.

Silicone molds for complex jewelry design

Flexible, easy to peel-off and heat resistant, silicone rubber is the material of choice to create jewelry molds

Lost-wax casting has been used for thousands of years to reproduce original jewelry pieces. This process, used by master craftsmen as well as home crafters, involves pouring a liquid metal alloy into a mold, using a wax model that melts away to leave a hollow chamber in the mold. For industrial or personal use, creating resin jewelry with silicone molds is by far the best option.

Silicone reusable vacuum bags for infusion molding

Reusable vacuum bag (RVB) silicone membranes improve the quality in composite molding

Fiber-reinforced polymer (FRP) composites are increasingly being used to make molded parts for a wide variety of industries: automotive (including trucks and off-road vehicles), renewable energy (components such as wind-turbine propellers), aerospace, marine construction and architectural structures. These composites combine excellent mechanical properties with a low density, and feature high resistance to water, chemicals and environmental conditions.

Silicone formulations for specific expansion molding requirements

Silicones enable accurate and cost-efficient expansion molding processes for composite materials

Composites, also known as composite materials, are fiber-reinforced resins or polymers intertwined in matrices, which are molded in expansive thermosetting processes to produce lightweight and highly resistant parts and structures.

Initially introduced and developed by the aeronautics and space industries to produce lighter and more durable parts previously made of metal alloys, composites have become cost-effective materials of choice for making cutting-edge components for a growing number of industries

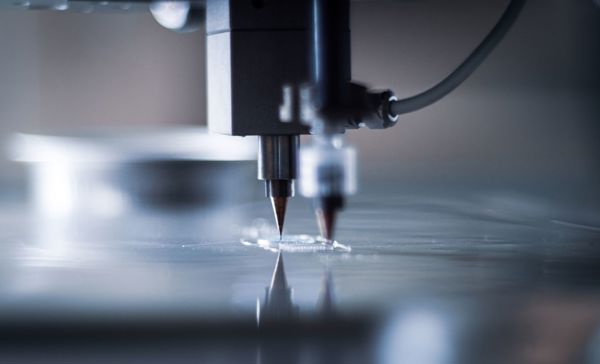

Silicones for 3D printing and additive manufacturing

Build your own capabilities to enhance your competitive edge

What if you could combine the unique versatility of silicones and with the flexibility of additive manufacturing (3D printing)? As one of the world’s leading fully integrated silicone manufacturers, Elkem Silicones has a clear objective to unlock the potential of additive manufacturing with silicone elastomers opening a wide range of opportunities that are impractical or even impossible using traditional processing techniques.

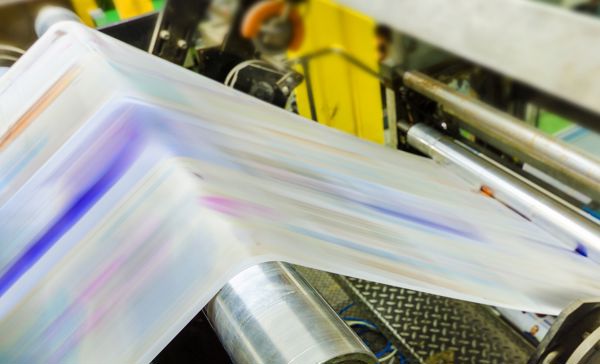

Silicones for pad printing

Printing all colors and all graphics on all surfaces of all shapes

Printing is essentially done with rollers for continuous runs on flat surfaces or by stamping with flexible pad printers for use on curved, uneven or multiple-face surfaces made from an endless number of materials.

For example, toymakers use pad printing to imprint very fine details on everything from plastic dolls to metal models; while cosmetics and skin care makers need to reproduce their logos and stylish images on everything from sophisticated perfume bottles to curved plastic tubes and ceramic cream jars. Quality pad printing is therefore an essential differentiator for manufacturers of consumer products to create distinctive and desirable items.

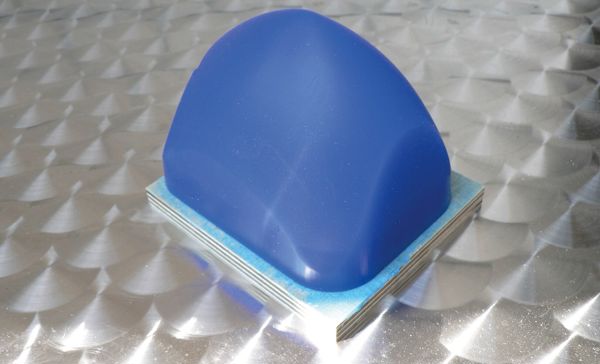

Silicone molds for rapid prototyping

Rapid prototyping with high fidelity

Rapid prototyping is an important step in the design development and approval process leading to higher-volume serial manufacturing. After having designed new virtual models in CAD systems, industrial customers often need to rapidly produce physical prototypes before launching into short/medium-run production. This is the stage when the new product comes to life and can be tested for its true performance specifications.

Whether you’re inspecting a new product in the board room or testing a functional part in the real-world, you need a part that accurately replicates your design. Your starting point defines your journey, and accurately reproducing that design with the help of silicones can be crucial to the whole process.

Silicones for roller printing

Developing a time-tested technology for printing quality ceramic tiles and new applications

Roller printing, based on laser engraving of designs onto silicone elastomers and foams, has for many years been synonymous with the most sophisticated designs for ceramic tiles.

This technique enables precise high-definition reproduction of complex designs and consistent levels of ink transfer based on multi-depth ink pockets – resulting in subtle color shades and the possibility of accurately reproducing modern geometrical graphics, achieving trompe-l’oeil patterns, imitating mosaics, or producing antique patina effects.

Silicone molds for metal casting

Silicone is an ideal art & foundry material for use when modelling

Art foundry is a technique used to mold sculptures, usually through the use of lost-wax casting. This centuries-old method, also known as cire-perdue, involves pouring molten metal into a mold that has been created by means of a model.

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.