- Elkem

- Products

- Carbon based materials

- Furnace tapping materials

Furnace tapping materials - ELTAP®

Ensuring reliable operation during the tapping of ferroalloys.

The furnace tapping process can be a hazardous operation, and demands that careful attention is paid to both taphole design, integrity and maintenance. For over 40 years, Elkem has provided high-quality taphole materials and tailored services to make tapping of ferro-alloys as efficient and as safe as possible.

Furnace tapping materials: Streamlining operation and improving safety for submerged arc furnaces

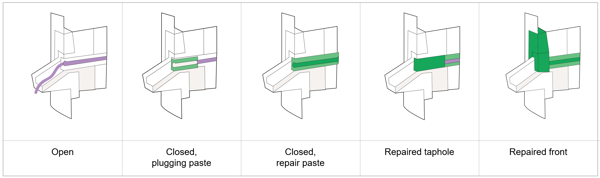

The tap holes of the submerged arc furnaces used in the smelting of ferroalloys and pure metals are a critical part of the furnace operation. These tapholes are subject to particularly challenging operating conditions, which include rapid swings between high and low temperatures, physical and chemical erosion from molten metal matte and slag, and the oxidation of carbon-based materials caused by exposure to air at elevated temperatures.

These challenges of critical importance can be tackled by the careful design of the taphole, use of the correct materials, and optimized maintenance. Done correctly, this can reduce the risk of accidents taking place during the frequently-repeated opening/closing procedures.

Tapping materials from Elkem

Since the 1980s, Elkem has been a major supplier of high-quality tapping products to the pyrometallurgical smelting industry, including supplying tap hole products for furnaces producing silicon, ferrosilicon, silicomanganese, calcium carbide, ferrochrome and ferromanganese.

Taphole materials for every requirement

The various tap hole procedures each have different requirements, and it is important to choose the correct material for the purpose to ensure a good result.

Short-term plugging and repairs (to temporarily seal the taphole between tapping sequences) are best carried out with a hybrid carbon-based material (such as ELTAP® G THL), which because of its quick-hardening, viscoelastic nature can be applied with a ‘mud gun’ at ambient temperatures.

Longer-term plugging and repairs to the taphole channel are ideally carried out within the taphole using special carbon-based self-flowing pastes such as ELTAP® G THP, which can be applied using a ‘mud gun’ after being heated.

Full tap block repairs (such as those to the tap hole front, tap hole block and surrounds) typically cannot be carried out using cold materials because of the difficulty in arranging access for the necessary tamping equipment. Instead, self-flowing pastes such as ELTAP® G SiC, ELTAP® E MA, and ELTAP® G THP are commonly used, which once preheated have good flow characteristics and resistance to oxidation.

Tapping launder repairs are best carried out ex situ, but can also be done in situ, with our rammable ELTAP® G SMB and ELTAP® G KR pastes. These pastes are easy to install, free of harmful PAHs, and offer optimum wear and oxidation.

High-quality ingredients

The main constituents of ELTAP® furnace tapping materials are electrically calcined carbon and silicon carbide, bound either with a PAH-free hydrocarbon-based binder, or with environmentally-friendly biopolymeric binders.

All these components are carefully sourced and prepared, guaranteeing robustness in operation and a long service life. The time invested in material development ensures that our products continue to meet the highest standards.

Pitch-free products for improved health & safety

None of our ELTAP® products contain coal-tar pitch, greatly reducing or eliminating harmful PAH emissions. This reduces the need for cumbersome protective equipment, and improves the safety of the working environment.

Easy handling and installation

Whether you chose a conventional self-flowing paste, or our viscoelastic ELTAP® G THL, our taphole materials are precisely engineered to make them both easy to handle and install.

The action of installing these materials has been optimized through years of practice and technology development.

Resistance to oxidation and wear

The majority of our ELTAP® furnace tapping materials are formulated with various additives in order to provide excellent resistance to oxidative degradation as well as strong resistance to wear and erosion.

Our most popular ELTAP® furnace lining materials are:

Product option

Description

ELTAP® E SiCT

Carbores-bound silicon carbide material with high oxidation resistance

ELTAP® HotSiC

Self-flowing silicon carbide material with high oxidation resistance

ELTAP® G SMB

Environmentally friendly carbon paste with increased oxidation resistance

ELTAP® E SM

Carbores-bound carbon paste with increased oxidation resistance

ELTAP® G KR

Resin-bound material with high tensile strength after curing

ELTAP® G THP

Self-flowing carbon paste for taphole repair

ELTAP® G THL

Ambient-temperature plugging and repair paste for tapholes suitable for mud guns

Excellent service from start to finish

Having a reliably-performing taphole is vital for you – and it’s a priority for us too. At Elkem, we’re ready to advise you on every aspect of selecting and installing taphole repair materials.

As part of our service, we can:

- Help you decide the optimum product for repairing your furnace taphole

- Quality-check installation procedures

- Ensure that the best temperature profile is maintained during curing

- Provide simulations of temperature and tap hole wear

- Advise on an entire taphole configuration

- Develop customized products

- Prepare a complete taphole installation plan.

In addition, because we recognize that no two furnaces are the same, we usually prepare all our batches of taphole materials to order. And with production facilities in Brazil, China and Norway, we’ll normally be able to get them to you within 2 months.

Sustainability at Elkem

To learn more about our sustainability initiatives, check our webpage.

Related products

Contact us

Reach out today to unlock your full potential with Elkem's safe, stable, and efficient solutions.